- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

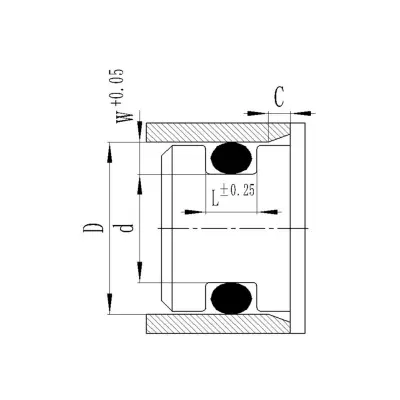

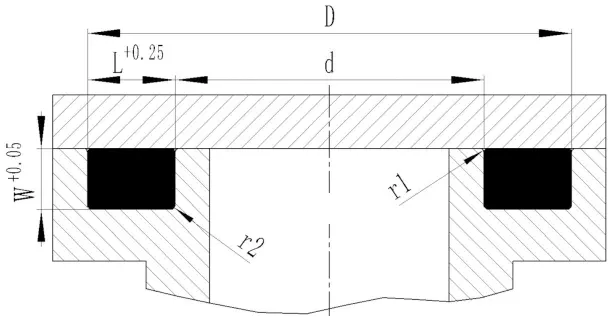

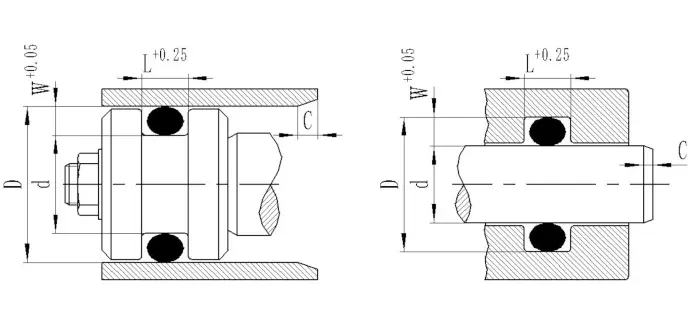

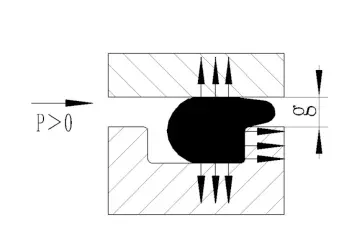

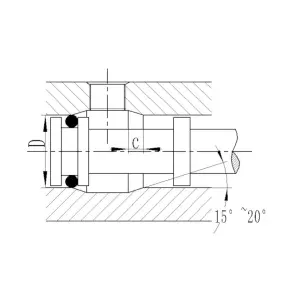

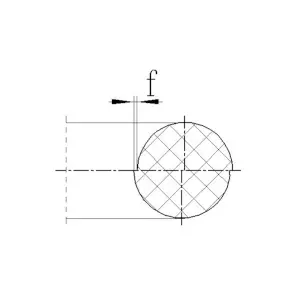

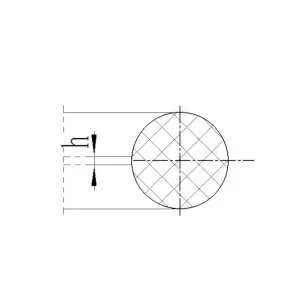

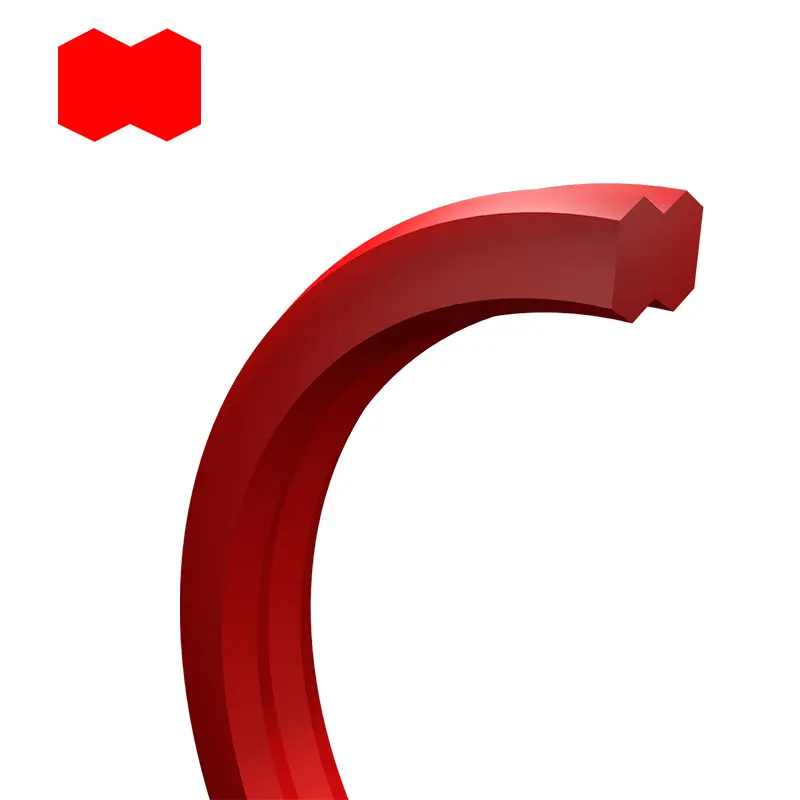

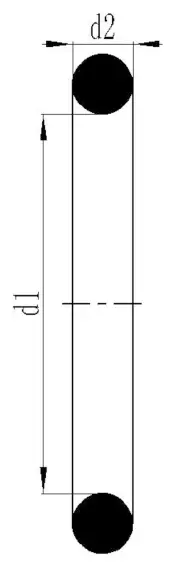

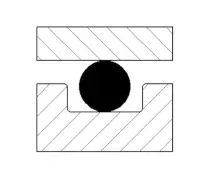

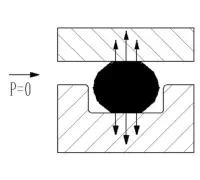

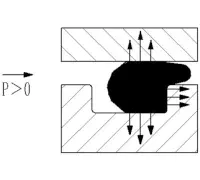

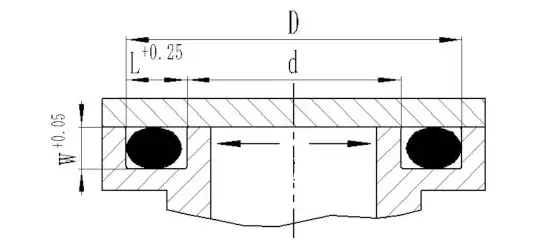

Internal pressure: The outer diameter of the O-ring and the outer diameter of the groove D should be basically close to or greater than 1~3%.

Internal pressure: The outer diameter of the O-ring and the outer diameter of the groove D should be basically close to or greater than 1~3%.

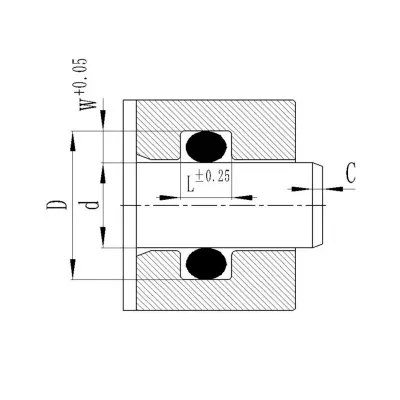

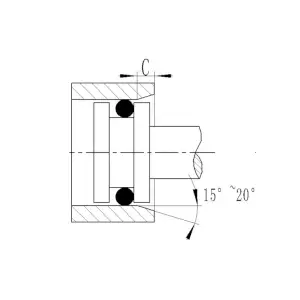

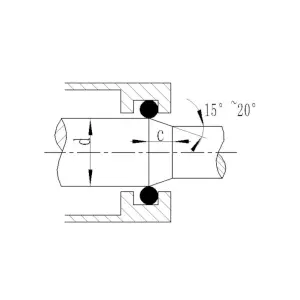

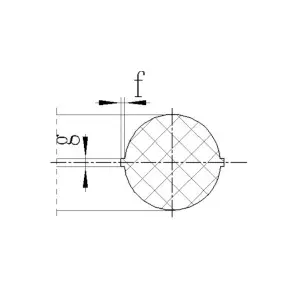

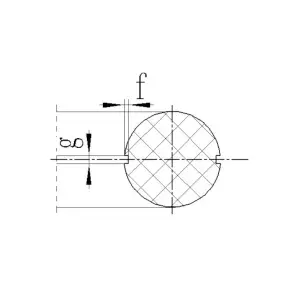

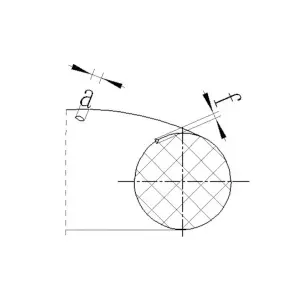

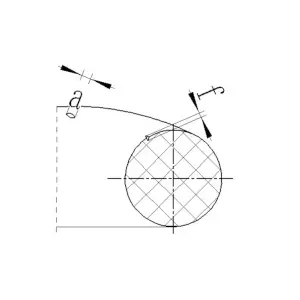

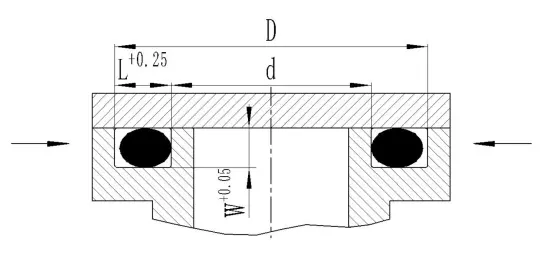

External pressure: The inner diameter of the O-ring should be close to or slightly smaller than the inner diameter d of the groove, but not less than 6%.

External pressure: The inner diameter of the O-ring should be close to or slightly smaller than the inner diameter d of the groove, but not less than 6%.